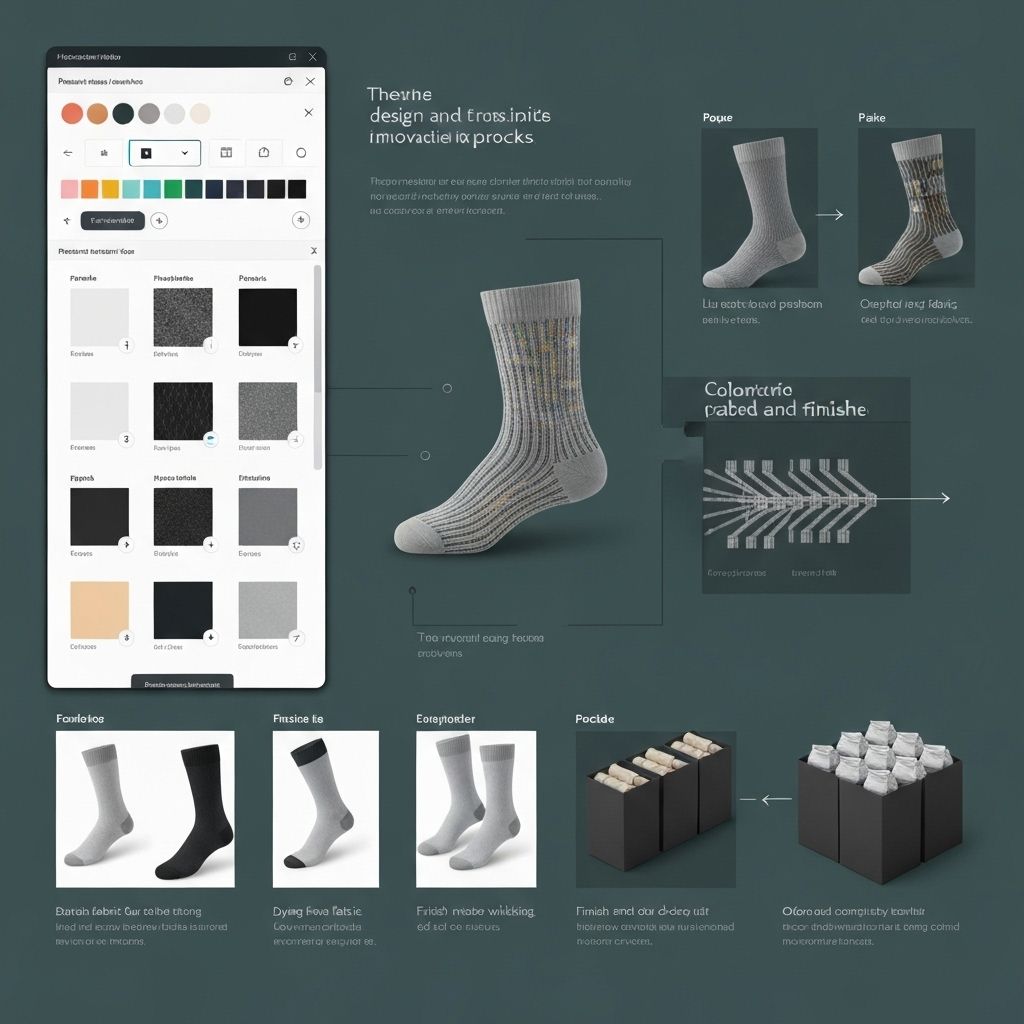

Understanding the custom sock manufacturing process helps wholesale buyers set realistic expectations, plan inventory effectively, and communicate requirements clearly. This comprehensive guide walks through each stage from initial concept to final delivery.

Phase 1: Design and Specification (Week 1-2)

The manufacturing journey begins with translating your vision into detailed technical specifications. This phase establishes the foundation for successful production.

Initial Consultation:

- Define target market and intended use (athletic, casual, dress, etc.)

- Establish budget parameters and target retail price point

- Determine order quantities and delivery timeline

- Discuss any special requirements (certifications, packaging, etc.)

Design Development:

- Create or refine artwork, logos, and patterns

- Select sock style (crew, ankle, no-show, knee-high)

- Choose material composition and yarn specifications

- Specify construction details (cushioning, compression, seamless toe)

- Define size range and grading

Professional manufacturers provide design templates and technical guidance to ensure your concepts are production-ready. Digital mockups help visualize the final product before committing to sampling.

Timeline: 3-7 business days for design finalization

Phase 2: Pre-Production Sample (Week 2-3)

Once designs are approved, the factory produces pre-production samples to validate all specifications before bulk manufacturing begins.

Sample Production Process:

- Program knitting machines with design specifications

- Source and prepare specified yarns and materials

- Produce 3-5 pairs per design for evaluation

- Apply any special treatments (moisture-wicking, antimicrobial)

- Complete finishing processes (linking, boarding, packaging)

Samples are shipped via express courier (3-5 days) for your evaluation. This is your opportunity to assess fit, comfort, color accuracy, and overall quality before approving bulk production.

Sample Evaluation Checklist:

- Color accuracy compared to Pantone references

- Design placement and proportions

- Material feel and quality

- Fit and sizing across size range

- Construction quality (seams, elasticity, finishing)

- Packaging and labeling

Minor adjustments (color tweaks, sizing modifications) can typically be accommodated without additional sampling. Major changes may require a second sample round.

Timeline: 7-10 business days for sample production and shipping

Phase 3: Bulk Production (Week 4-7)

After sample approval, bulk manufacturing begins. Production time varies based on order quantity, complexity, and factory capacity.

Production Stages:

1. Material Procurement (3-5 days):

- Order yarns in required colors and quantities

- Source packaging materials and accessories

- Prepare any custom labels or hang tags

2. Knitting (7-14 days):

- Program and set up knitting machines

- Produce sock tubes according to specifications

- Monitor quality throughout production run

- Typical output: 200-400 pairs per machine per day

3. Linking and Finishing (3-5 days):

- Close toe seams (hand-linked or machine-linked)

- Steam and board socks to final shape

- Apply any special treatments or coatings

- Trim loose threads and inspect for defects

4. Packaging (2-3 days):

- Pair and size-sort socks

- Apply labels, tags, and stickers

- Package according to specifications (poly bags, boxes, hangers)

- Prepare cartons for shipping

Production Timeline by Order Size:

- 500-1,000 pairs: 15-20 business days

- 1,000-3,000 pairs: 20-25 business days

- 3,000-10,000 pairs: 25-35 business days

- 10,000+ pairs: 35-45 business days

Rush production is available for urgent orders, typically reducing timelines by 30-40% with an additional 15-20% cost premium.

Phase 4: Quality Control (Week 7-8)

Comprehensive quality control ensures your order meets specifications before shipping. Professional manufacturers implement multi-stage inspection protocols.

Quality Control Checkpoints:

In-Process Inspection:

- Monitor knitting quality during production

- Check color consistency across batches

- Verify sizing and measurements

- Identify and correct issues immediately

Final Inspection (AQL 2.5 Standard):

- Random sampling inspection of finished goods

- Measure dimensions and weight

- Assess construction quality and finishing

- Verify packaging and labeling accuracy

- Test elasticity and durability

Common Defects Screened:

- Holes, snags, or loose stitches

- Color variations or dye defects

- Sizing inconsistencies

- Improper toe seams or linking

- Packaging errors or missing components

Third-party inspection services are available for large orders or when additional verification is desired. Inspection reports with photos document quality status before shipping.

Timeline: 2-3 business days for final inspection

Phase 5: Shipping and Logistics (Week 8-10)

After passing quality control, orders are prepared for international shipping. Logistics planning ensures timely, cost-effective delivery.

Shipping Options:

Air Freight (5-7 days):

- Fastest delivery option

- Ideal for urgent orders or small quantities

- Higher cost per unit ($3-8 per kg)

- Door-to-door service available

Sea Freight (25-35 days):

- Most economical for large orders

- Suitable for planned inventory replenishment

- Lower cost per unit ($0.50-1.50 per kg)

- Requires customs clearance and inland transport

Express Courier (3-5 days):

- Premium speed and convenience

- Best for samples and small orders

- Highest cost per unit ($8-15 per kg)

- Simplified customs clearance

Documentation and Customs:

- Commercial invoice with accurate product descriptions

- Packing list detailing contents and quantities

- Certificate of origin (if required for duty benefits)

- Any required compliance certifications

Experienced manufacturers handle export documentation and can recommend freight forwarders for smooth customs clearance.

Total Timeline Summary

Standard Production Timeline:

- Design and Specification: 1-2 weeks

- Pre-Production Sample: 1-2 weeks

- Bulk Production: 3-5 weeks

- Quality Control: 3-5 days

- Shipping: 1-5 weeks (depending on method)

Total Time from Order to Delivery:

- Air Freight: 8-10 weeks

- Sea Freight: 10-14 weeks

First-time orders typically take longer due to design development and sample approval. Reorders of existing designs can be expedited significantly.

Best Practices for Smooth Production

- Plan Ahead: Order 3-4 months before you need inventory

- Clear Communication: Provide detailed specifications and reference samples

- Realistic Expectations: Understand that custom manufacturing takes time

- Sample Approval: Thoroughly evaluate samples before approving bulk production

- Payment Terms: Understand deposit and balance payment schedules

- Quality Standards: Agree on acceptable quality levels (AQL) upfront

- Contingency Planning: Build buffer time for unexpected delays

Conclusion

Custom sock manufacturing is a collaborative process requiring clear communication, realistic timelines, and attention to detail. Understanding each phase helps you plan effectively and work productively with your manufacturing partner.

At Velon Socks, we guide clients through every step of the process with transparent communication, regular updates, and quality assurance at each stage. Our experienced team has produced over 10 million pairs of custom socks for clients worldwide, and we're ready to bring your vision to life.